Lee 408 Water Jet Loom

Description:

Technical Feature:

1. Optimize the overall design of loom to make the frame more stable, high efficiency, better fabric quality;

- Optimized beating design; Beating force greater, suitable for high density, high speed fabric;

3.LEE-408/410 series of water jet weaving has been extensively strengthened in the body, also has greatly improved waterproofing, weaving can be widely applied to a variety of fabrics, the maximum speed can reach 1200RPM;

4 .75D fabric, for example, the highest latitude up to 78Pick / cm (198 per inch)

Lee 408 Water Jet Loom Technical Parameters:

| 1 | The LEE – 851/873 series have widely strengthen in the fuselage of water jet loom; |

| 2 | Suitable for most of water jet fabric weaving; It can be widely used all kinds of fabric weaving |

| 3 | Also has a great improvement in terms of waterproof, top speed can reach 1000 RPM. |

| 4 | For example, 75d fabric, the highest weft density : 50pick per cm(127 pick per inch) |

Lee 408 Water Jet Loom Technical Specification:

| Nominal reed space(cm) | 150/170/190/210/230/260/ | 280/300/340/360/420/460/540 |

| Effective Width | Max-50cm (standard) | Max-70cm (standard) |

| Nozzle Quantity | Single Nozzle/Double Nozzle/Triple Nozzle/Quadruple Nozzle | |

| Shedding Type | Plain Shedding/Cam Shedding/Dobby Shedding/Jacquard Shedding | |

| Beating Up | 4-linkage crank beating-up (standard for common hollow shaft) | |

| Scissors and feeler | Mechanical ceramic scissors; Double photoelectric weft detector | |

| Beam diameter | φ 800 mm,φ1000 mm (optional) | |

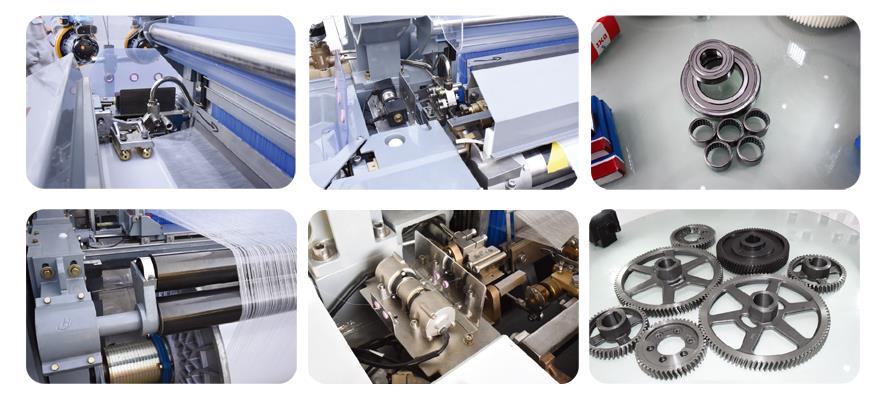

Technical Improvement:

1. Loom Structure

The main wall of the loom adopts high grade cast iron; the main beam adopts shaped seamless steel pipe; the whole frame is more stable, reducing the vibration during high-speed operation and ensuring the high quality and high output of the fabric. At the same time on the large wall panels, wall panels, side cover tempering treatment is not deformed.

2. Shedding System

The utility model has the advantages of increasing the size of the open connecting rod and the vertical shaft and the like; the double-bones and broadside (120mm) heavyweight heald frames ensure stable and reliable warp yarn openings at high speed and medium-thick weaving fabrics;

3. Weft yarn feeler device

Sensitive optical feeders; from the original yarn to strong twist yarn, from low denier to high denier can be accurately detected; broken weft stop in time to prevent the occurrence of weaving defects.

4.Temple Device

Change from 3 row finger to five row finger; Enlarge edge rod and cloth guide steel size; Power full temple make fabrics more stable.

5. Leno cloth edge

The edge of the cloth is in the shape of a rope; the edge of the cloth is fastened and is not easy to be loosened; the thickness is basically the same as that of the ground, without chromatic aberration after dying; the aluminum alloy planetary gear wheel is provided with a light edge and low vibration for high speed operation; Nylon ring gear, reduce noise, easy to replace.

6.Aluminum alloy parts

Suction pipe seat / weaving edge gear and so on all the anode hard film treatment; both beautiful and wear-resistant; sley, slide from aluminum to stainless steel parts; so that it not only increases the strength, but also increased corrosion resistance.

7.Centralized oil supply system

Easy operation; simplified equipment lubrication and maintenance; centralized turbid system to ensure the normal operation of equipment lubrication.

8.Beat Device

Crank rod mechanism inertial beat-up; crankshaft with high-frequency quenching and other special processing, improve the wear resistance, hardness and strength; rocker shaft diameter, using ⌀ 114 × 10mm seamless steel pipe; Recessed feet, enhanced strength, to ensure life; sley, slide stainless steel material to improve the beating force, can be woven high density and medium thick fabric, cloth tight, fullness.

9. Side Cutter device

The use of ceramic or carbide cutting edge; both sharp and wear-resistant; coupled with imported rod ends bearing, regardless of the thickness of weft, can be accurately cut off.

10. Bearing, crankshaft

The use of Sweden SKF Germany FAG, Japan NSK imported bearings; the crankshaft quenching to further improve the degree of crankshaft wear and tear; extended service life.

11. Let Off device

Semi-positive continuous feed mechanism, bold double roller (⌀113mm) warp tension detection; with the most advanced stepless CVT to adjust the amount of feed; friction plate pressure device to prevent the sending and unwinding fluctuations; For medium-thick fabrics and to ensure that the tension through the tension and stability.

12. Electronic Take Up

Small body design; Large output power, easy to adjust; Fully automatic operation of all kinds of fibers; Ensure that the weaving process is always in sync.

13. Electronic Let Off

Make the warp tension remained stable; to meet the needs of a variety of fabrics; can improve the fabric grade; fabric varieties more convenient and efficient replacement, improve production efficiency.

Download Technical Specification Sheet

Download the brochure