Business story

Junior high school education, start business from 120,000 CNY, now Mr Xu’s Polyester Taffeta “hot sale!”

Guide: After graduating from junior high school, Mr XU Yuehua helped his parents at home to operate looms. He came into the printing and dyeing enterprises in 1999, from the cylinder block to the group leader, and then to the workshop director. Due to the growing disparity in the quality of life of helpless and good friends, he decided to resign and start his own business. With the will to dare to fight and the vision to be far-sighted, Xu borrowed money and contracted (rent) a production line at the very beginning and now owns a weaving company that hold hundreds of looms. Today, he is the boss of Wuxi Xianghua Printing and Dyeing Co., Ltd. and Anhui Mingwang Chemical Fiber Co., Ltd. and many other textile companies!

Xu Yuehua, Born in Ping Wang,Suzhou city, operated K611 weaving machines for his parents after graduating from junior high school. With the upgrading of weaving machines, more and more write gray fabrics are on the market, and dyeing factories have also emerged. In 1999, he entered a dyeing and finishing enterprise. He started working as a blocker at the grassroots level. He successively engaged in shaping machines, team leaders, on-duty shifts, and workshop directors. The steady income and comfortable working rhythm made Xu Yuehua feel satisfied at the time.

“In the Spring Festival in 2006, my childhood buddy drove a bens while I was driving a motorcycle. I didn’t even dare to take off my helmet.”

Although the steady work is good, it cannot significantly improve the quality of life. With the family members did not understand and did not support the case, Xu Yuehua and his wife decided to resign from the job of the director of the workshop and start their own entrepreneurship.

No money to build dyeing factory, Mr Xu first borrow money to rent production line

Earn savings from the early work, and borrowed some money from the relative, Xu Yuehua rented a production line with a rental fee of RMB 120,000 to a certain printing and dyeing company. During this period, he slowly accumulated business and contacts. In 2014, Xu Yuehua and four partners established Wuxi Xinchao Dyeing and Finishing Co., LTD

“When it came to Xinchao, there were only 2 sets of stretch setting machines and 10 sets of dyeing vat machines,” said Xu Yuehua. “After several years of development, the number of trendy devices has now turned several times. The number of setting machines has increased to 8 and dyeing machines have increased to More than 70 sets, annual processing output value can reach more than 100 million.”

The industry generally believes that new equipment is far superior to old equipment in terms of production performance, but Xu Yuehua does not think so. “It’s not just a new machine that can make a good product.” Xu Yuehua said with a smile. “More than 70 new gadgets are used. I don’t have diamonds, so I can still use porcelain.”

The industry generally believes that new equipment is far superior to old equipment in terms of production performance, but Xu Yuehua does not think so. “It’s not just a new machine that can make a good product.” Xu Yuehua said with a smile. “More than 70 new gadgets are used. I don’t have diamonds, so I can still use porcelain.”

Originally, although the new equipment is superior in terms of production efficiency, it takes a long “break-in period” for the actual processing of a certain category of textiles. According to the product characteristics of different categories, Xu Yuehua adjusted the internal structure and electrical system of the equipment through technical means, and accelerated the speed of the equipment to adapt to actual production. For example, 1680 bags of products, through the adjustment of the internal structure of the dyeing tank, to avoid the cracking yarn and tissue displacement problems in the processing process.

Weaving ourselves and dyeing ourselves

In the process of operating the dyeing factory, Xu Yuehua discovered that the printing and dyeing industry will experience a phenomenon of light season. During the peak season, orders were too late to process, and customers also urgently demanded finished products. In the off-season, not to mention the fact that the production line was not operating properly, it was necessary to look at the customer’s eyes when connecting orders. How to solve the low season orders has become Xu Yuehua has been thinking about.

Weaving ourselves and dyeing ourselves

In the process of operating the dyeing factory, Xu Yuehua discovered that the printing and dyeing industry will experience a phenomenon of light season. During the peak season, orders were too late to process, and customers also urgently demanded finished products. In the off-season, not to mention the fact that the production line was not operating properly, it was necessary to look at the customer’s eyes when connecting orders. How to solve the low season orders has become Xu Yuehua has been thinking about.

By chance, Xu Yuehua purchased a white gray fabric from an Anhui weaving factory. The other party did not deliver on time, and fabricated various reasons for perfunctory congestion. Xu Yuehua decided to personally visit this factory to find out the reasons. Originally, the other party’s enterprise was “half-dyed” and basically stopped production. Xu Yuehua analyzed the reasons for his failure and discovered a number of “lethal” problems. Xu Yuehua realized that this is an excellent opportunity for himself.

“After I came back, I had the idea of ”renting the weaving factory and doing it myself.”

This decision at that time required great courage because acquiring a company required a lot of money. “The money is not enough, let me rent it first!” said Xu Yuehua, who had rented a 50-Chinese acre weaving plant in 2015! The knife has to be sharpened! Xu Yuehua’s emphasis on talented people is no exception. Early in the development of weaving plants, high-paying skilled workers were recruited at high pay. With a strong product quality, the brand awareness has quickly become popular in the local area!

Hard work pays off. Under the management of Xu Yuehua, Anhui Mingwang Chemical Fiber Co., Ltd. (hereinafter abbreviated as Anhui Mingwang) has been acquired from the original leased land and plant to the current full amount. The equipment has also been added to more than 300 water-jet looms, 2 slushing machines, 1 boiler, 2 dryers, more than 10 washing machines, and 2 sewage treatment systems.

Dyotav “can’t find anything”, it can’t be sold at all.

Recently, in the Shengze textile market, Ditafu has become a “hot commodity,” and many businesses may not be able to buy cash holdings. Xiao Bian also wondered why the process was the simplest and why Dita’s price was the cheapest.

Originally, with the relocation of water jet looms, the local production of polyester taffeta in Shengze has continued to decrease; and the water jet weaving enterprises that have migrated to other places have not produced the supporting facilities (such as sizing and steaming) Supply, washing and drying, etc., together with the increase in the cost of transportation from Ditafu to Shengze, led to Ditafu’s “difficult to demand” phenomenon in the Shengze market.

Anhui Mingwang mainly produces various kinds of polyester taffetas, with monthly production of up to 3 million meters, and has opened two salesrooms in Shengze to meet market demand. It is reported that Xu Yuehua has adjusted the production mode of traditional weaving mills, lengthened the production line, changed the production process to reduce unnecessary costs, and increased the net profit of products. Under the leadership of Xu Yuehua, the annual output value of Anhui Mingwang has grown wildly.

“Two ways for the long-term development of the company: the lowest price, the most advanced.”

Ideas determine the way out. Xu Yuehua knows well that such growth is unsustainable and must find its own core competitiveness in a homogenous market competition. Pingwang Textile is increasing its capital investment and researching and developing refined polyester taffeta, which will greatly increase its profits compared with ordinary polyester taffeta products on the market. In addition, Xu Yuehua will also enrich product diversity, get involved in the field of apparel fabrics, and create an industrial and trade integrated industrial cluster.

Postscript:

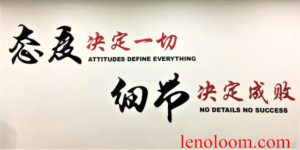

Apart from business, Xu Yuehua’s greatest hobby is learning, especially for the Confucian culture. He used the interesting question of “How Caterpillars Cross the River” to analyze the dialectical relationship between “waiting for opportunities” and “creating opportunities”, which is easy to understand. As the slogan in his office said, attitude is everything and details determine success or failure. Do it first, then be stronger and finally bigger! To study hard on one thing and keep learning will surely succeed. Even the most common Dita!

Leave A Comment